- chamundaindustries@yahoo.com

- +91 72839 20424, +91 98790 26768

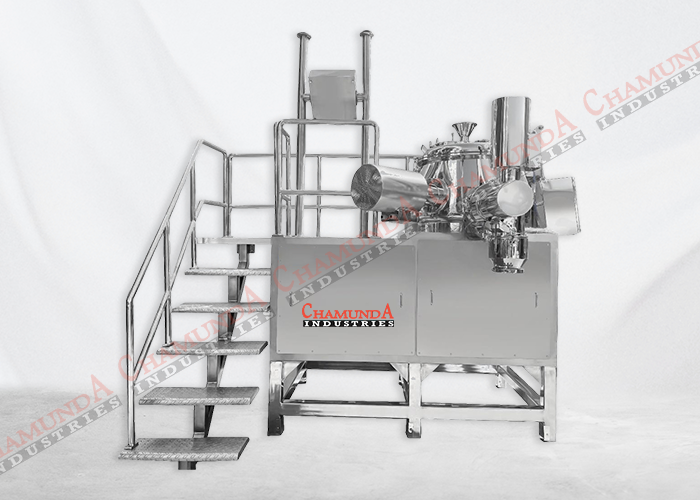

Salient Features :

- In compliance with cGMP procedures/regulations

- Models available from 3 to 1250 Liter

- Fully automatic operation based on PLC-HMI with color touch screen control

- Contact parts SS 316 or 316L quality

- Uniform mixing & granulation

- Less handling or hygienic

- Robust in construction

- The basic structure is made up of stainless steel 304 quality heavy duty square pipe covering from outer side with stainless steel 304 quality sheets as well

- Anti vibration mountings provided

- Mixing container in vertical, cylindrical-conical design

- Adequate mixing & granulating time

- Electro-Pneumatic product discharge system

- Electro-Pneumatic lid opening system

- Effective sealing to prevent leakage

- Shaft seal with gland and having air purging design for both mixing impellor & chopper

- The impeller mixing blade consists of advanced three blades specially designed for intense mixing. The angles of the blades are designed to ensure homogeneous mixing of different ingredients. The mixing blade assembly is mounted on the main shaft with separate bearing housing which fully eliminates any chance of cross contamination of product with any lubricants

- Easy to clean & maintain

- All contact surfaces for the product are polished & made to a mirror finish, while non-contact surface & outer finish is made to a matt finish/polish

- AC variable frequency drives (VFD) for both mixing impellor & chopper motor

- Flameproof (FLP) motors/electricals available (optional)

- Inline wet cone mill with AC VFD available (optional)

- Binder addition spray system (optional)

- CIP/WIP system (optional)

- Jacketed bowl with temperature control/display (optional)

- In compliance with 21 CFR Part 11 (optional)

- Innovative Swing type lid opening arrangement instead of conventional (optional)

- Integrated transfer system to Fluid Bed Dryer or another machine (optional)

- Automatic powder loading to the bowl through either L&P (Lifting & Positioning) system or Powder transfer system (PTS) through vacuum (optional)

Technical Specifications :

| Rapid Mixer Granulator/ High Shear Mixer Granulator - TECHNICAL SPECIFICATIONS | |||||||||||

| MODEL | CI-RMG-50 | CI-RMG-100 | CI-RMG-150 | CI-RMG-250 | CI-RMG-300 | CI-RMG-400 | CI-RMG-600 | CI-RMG-800 | CI-RMG-1000 | CI-RMG-1200 | CI-RMG-1250 |

| Gross Volume in Liter | 50 | 100 | 150 | 250 | 300 | 400 | 600 | 800 | 1000 | 1200 | 1250 |

| Maximum Working Volume in Liter | 40 | 80 | 120 | 200 | 240 | 320 | 480 | 640 | 800 | 960 | 1000 |

| Batch Size (kg) Min. & Max. | 10 to 20 | 20 to 40 | 30 to 60 | 50 to 100 | 60 to 120 | 80 to 160 | 120 to 240 | 160 to 320 | 200 to 400 | 240 to 480 | 250 to 500 |

| Impellor/Mixer Motor (HP) - 750 to 1500 RPM | 7.5 | 10 | 15 | 30 | 30 | 40 | 50 | 60 | 75 | 100 | 100 |

| Chopper Motor (HP) - 1500 to 2800 RPM | 3 | 3 | 5 | 5 | 5 | 7.5 | 7.5 | 10 | 15 | 15 | 15 |

| Total Power (HP) | 10.5 | 13 | 20 | 35 | 35 | 47.5 | 57.5 | 70 | 105 | 115 | 115 |

| Compressed air Pressure (bar) | 6 to 7 | ||||||||||

| Electrical supply | 3 Phase AC, 415 or 380 or 220 Volts+ 10%, 50 or 60 Hz | ||||||||||